Concept explainers

The Action Toy Company has decided to manufacture a new train set the production of which is broken into six steps. The demand for the train is 4,800 units per 40-hour workweek:

a) Draw a precedence diagram of this operation.

b) Given the demand, what is the cycle time for this operation?

c) What is the theoretical minimum number of workstations?

d) Assign tasks to workstations.

e) How much total idle time a present each cycle?

f) What is the efficiency of the assembly line with five stations? With six stations?

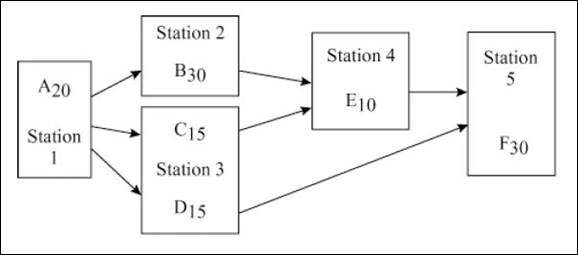

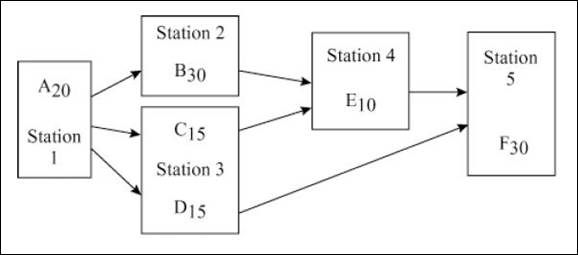

a)

To draw: The precedence diagram.

Answer to Problem 15P

Explanation of Solution

Given information:

| Task | Time (seconds) | Immediate predecessors |

| A | 20 | - |

| B | 30 | A |

| C | 15 | A |

| D | 15 | A |

| E | 10 | B, C |

| F | 30 | D, E |

| Total | 120 |

- Weekly demand is 4,800 units / 40 hours workweek.

Precedence diagram:

b)

To determine: The cycle time.

Introduction:

Cycle time:

Cycle time is the total time taken to complete an unit of work from the beginning of the process to the end of the process.

Answer to Problem 15P

The cycle time is 30 seconds / unit.

Explanation of Solution

Given information:

| Task | Time (seconds) | Immediate predecessors |

| A | 20 | - |

| B | 30 | A |

| C | 15 | A |

| D | 15 | A |

| E | 10 | B, C |

| F | 30 | D, E |

| Total | 120 |

- Weekly demand is 4,800 units / 40 hours workweek.

Formula to calculate cycle time:

Calculation of cycle time:

The cycle time is 30 seconds / unit.

c)

To determine: The theoretical minimum number of workstations.

Answer to Problem 15P

The theoretical minimum number of workstations is 4 workstations.

Explanation of Solution

Given information:

| Task | Time (seconds) | Immediate predecessors |

| A | 20 | - |

| B | 30 | A |

| C | 15 | A |

| D | 15 | A |

| E | 10 | B, C |

| F | 30 | D, E |

| Total | 120 |

- Weekly demand is 4,800 units / 40 hours workweek.

- Average daily demand is 50 chairs.

Formula to calculate theoretical minimum number of workstations:

Calculation of theoretical minimum number of workstations:

The theoretical minimum number of workstations is 4 workstations.

d)

To assign: The different tasks to different workstations.

Explanation of Solution

Assignment of different tasks to different workstations:

| Workstation | Elligible tasks | Selected tasks | Task time (seconds) | Available cycle time (seconds) | Remarks |

| 1 | 30 | ||||

| A | A | 20 | 10 | Task A is the only elligible ask | |

| 10 (Idle Time) | No other elligible task is available | ||||

| 2 | 30 | ||||

| B, C, D | B | 30 | 0 | Task B has the highest task time | |

| 3 | 30 | ||||

| C, D | C | 15 | 15 | Task C is assigned | |

| D | D | 15 | 0 | Task D is assigned | |

| 4 | 30 | ||||

| E | E | 10 | 20 | Task E is the only elligible task available | |

| 20 (Idle time) | The available cycle time is less than the task time | ||||

| 5 | F | F | 30 | 0 | Task F is assigned |

| Workstation | Task assigned | Idle time |

| 1 | A | 10 |

| 2 | B | 0 |

| 3 | C, D | 0 |

| 4 | E | 20 |

| 5 | F | 0 |

| Total | 30 |

e)

To determine: The idle time per cycle.

Answer to Problem 15P

The idle time is 30 seconds / cycle.

Explanation of Solution

Given information:

| Task | Time (seconds) | Immediate predecessors |

| A | 20 | - |

| B | 30 | A |

| C | 15 | A |

| D | 15 | A |

| E | 10 | B, C |

| F | 30 | D, E |

| Total | 120 |

- Weekly demand is 4,800 units / 40 hours workweek.

- Average daily demand is 50 chairs.

Calculation of idle time per cycle:

The idle time is 30 seconds / cycle.

f)

To determine: The efficiency.

Introduction:

Efficiency:

Efficiency is the measure of what is actually produced as opposed to what can be theoretically produced with the same amount of resources.

Answer to Problem 15P

The efficiency with five and six workstations is 80% and 66.6% respectively.

Explanation of Solution

Given information:

| Task | Time (seconds) | Immediate predecessors |

| A | 20 | - |

| B | 30 | A |

| C | 15 | A |

| D | 15 | A |

| E | 10 | B, C |

| F | 30 | D, E |

| Total | 120 |

- Weekly demand is 4,800 units / 40 hours workweek.

- Average daily demand is 50 chairs.

Formula to calculate efficiency:

Calculation of efficiency for five workstations:

Calculation of efficiency for six workstations:

The efficiency with five and six workstations is 80% and 66.6% respectively.

Want to see more full solutions like this?

Chapter 9 Solutions

Principles Of Operations Management

- The three-station work cell illustrated in the figure below has a product that must go through one of the two machines at station 1 (they are parallel) before proceeding to station 2. Q Capacity: 30 units/hr Station 1 Machine A Station 1 Machine B Capacity: 30 units/hr Station 2 Capacity: 10 units/hr a) The bottleneck time of the system is b) What is the bottleneck station of this work cell c) What is the throughput time? Station 3 Capacity: 6 units/hr minutes per unit (enter your response as a whole number).arrow_forwardEmployees Layoffs at the University Medical Center The University Medical Center is medium-sized, 300-bed capacity hospital at Dasmarinas Cavites. The facilities have grown gradually over the years and are now the 2nd largest in the town of Dasmarinas. It is entirely nonunion and has never experienced an employee layoff since its inception. Sister Veronica Cornista, the Chief Executive Officer of the hospital for 8 years presented a rather bleak financial of the BOD. This according to her is the result of the declining occupancy rate which has affected the hospital’s revenues to such an extent that it ran a deficit for the first time last 1998. Such declines have not been unusual for this industry because of increasing competition. So far, the only response to these changes has been tightening of requirements for equipment or supply purchases. The projected deficit for the coming year is around 1,300,000 unless some additional revenues were identified or some additional savings…arrow_forwardPlease answer question d, e, f a. Draw a precedence diagram.b. What cycle time would provide the desired output? c. What is the maximum possible output of the line? d. What is the theoretical minimum number of workstations using the cycle time computed in” b “above? e. Assign tasks to workstations using the cycle time in “b” above. f. Calculate the efficiency and idle time percentage of the line.arrow_forward

- QRS Corp is designing a product layout for a new product. They plan to use this production line 9 hours a day in order to meet forecasted demand of 600 units per day. Calculate the cycle time in seconds.. Calculate the minimum number of work stations if the sum of the task times is 170 secs Edit Format Table 12pt v Paragraph v BI UAV MacBook Air 80 esc F3 F5 F6 F7 FB F9 F1 F2 F4 @ # $ & 2 3 7 8 W R IIIY この COarrow_forwardDefine the concept of Bottleneck? Explain what system capacity is? Explain why doubling the capacity of a bottleneck may not double the system capacity?arrow_forwardA local toy manufacturer is using a production line that runs 8 hours per day and produces a toy that requires a total of 7 tasks to be performed. The daily demand is 120 toys. Times of the tasks are 2.73, 2.01, 2.13,20,2.61,2.71, and 2.95 minutes for A. B. C.D.E.F.and G,respectively. However, due to the nature of the product there are precedence rules that must be observed. Such that Task A does not need any predecessors: task B requires taskA to be completed. To start task C and task D, each require task B to be completed. Task C must be completed prior to stating task E. Task F needs both task D and task E to be completed. Finally, task Gcan start only once task Fis completedWhat is the minimum number of workstations needed? O a 8 O b. None of them O C. 5 d. 4 6.arrow_forward

- Sue Helms Appliances wants to establish an assem-bly line to manufacture its new product, the Micro Popcorn Popper. The goal is to produce five poppers per hour. The tasks,task times, and immediate predecessors for producing one MicroPopcorn Popper are as follows:TASK TIME (min) IMMEDIATEPREDECESSORSA 10 —B 12 AC 8 A, BD 6 B, CE 6 CF 6 D, Ea) What is the theoretical minimum for the smallest number ofworkstations that Helms can achieve in this assembly line?b) Graph the assembly line, and assign workers to workstations.Can you assign them with the theoretical minimum?c) What is the efficiency of your assignment?arrow_forwardA Manufacturing Corp. with three-station work cell has the process displayed below. Each workstation has only one worker to the assigned activity. Single order arrives every 7.5 hours.a) What is the minimum throughput time and WIP of this work cell?b) What is the maximum throughput? IN Station 1 OUTTask Time: 3 hrs.Station 2Task Time: 5 hrs.Station 3Task Time: 2 hrs ??arrow_forwardThe Action Toy Company has decided to manufacture a new train set, the production of which is broken into six steps. The demand for the train is 4,800 units per 40-hourworkweek: c) What is the theoretical minimum number of workstations? d) Assign tasks to workstations. e) How much total idle time is present each cycle?arrow_forward

- Tailwind, Inc., produces high-quality but expensive training shoes for runners. The Tailwind shoe, which sells for $210, contains both gas- and liquid-filled compartments to provide more stability and better protection against knee, foot, and back injuries. Manufacturing the shoes requires 10 separate tasks. There are 400 minutes available for manufacturing the shoes in the plant each day. Daily demand is 60. The information for the tasks is as follows: Performance Time Task (in minutes) 1 Н ABCDEFGH Task Must Follow This Task C, D ABB GAFG 324-325- E, H 25 312 | Required: a. Draw the precedence diagram showing the task precedence and their times b. Determine the cycle time associated with the rate of output required. c. What is the theoretical minimum number of work stations required to satisfy this output rate? d. Allocate the tasks to work stations taking into consideration the precedence requirements and using the LOT rule to break ties between feasible tasks. e. What is the…arrow_forwardThe three-station work cell at Pullman Mfg., Inc.is illustrated in Figure S7.8. It has two machines a t station I inparallel (i.e., the product needs to go through only one of the twomachines before proceeding to station 2). a) What is the throughput time of this work cell?b) What is the bottleneck time of this work cell?c) What is the bottleneck station?d) If the firm operates 8 hours per day, 6 days per week, what isthe weekly capacity of this work cell?arrow_forwardManufacturing Company uses FIFO method of accumulating costs in a two-department process. Materials are introduced at the inception of the process except for a special material which is added in department 2 at 60% completion as to overhead. Inspection is done at the end of the process in both departments. Production data for Department 2 are given below: In process, beginning, (80% labor, 70% overhead)2,000 Transferred in 14,900 In process, ending (40% labor, 20% overhead) 3,000 Normal spoilage 200 Abnormal spoilage (found at 30% completion as to laborand 15% as to overhead due to internal failure) 400 Cost data for the month:In process beginning:Transferred in 15,020 Special materials 1,900 Direct labor 4,388 Overhead 11,044 Current costs:Transferred in 137,080 Special materials 14,030 Direct labor 46,000 Overhead 113,564 The cost of units transferred to finished goods is?The cost of spoilage charged to revenue is?arrow_forward

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,

Practical Management ScienceOperations ManagementISBN:9781337406659Author:WINSTON, Wayne L.Publisher:Cengage,